I. Market Overview

Caprolactam (CPL), as the core monomer of Nylon 6, spans three major sectors: fibers, engineering plastics, and films, demonstrating strong cyclical resilience and integration dividends.

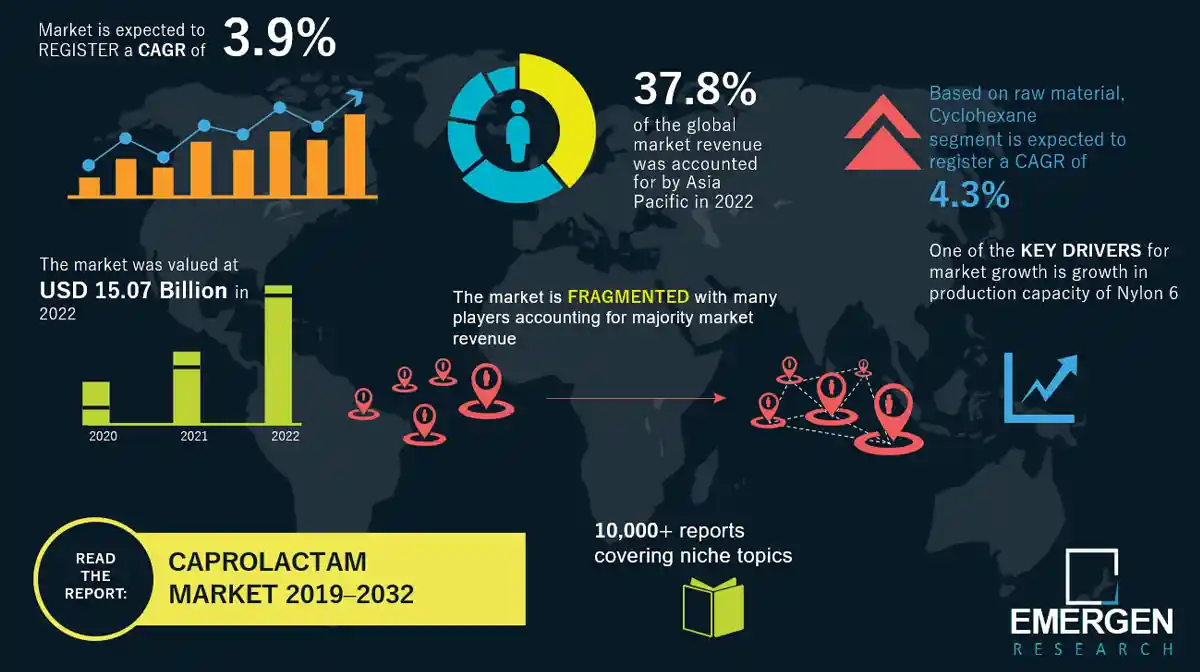

According to statistics, the global caprolactam market reached $12.28 billion in 2023 and is projected to reach $18.71 billion by 2030, with a compound annual growth rate (CAGR) of approximately 6.3% from 2024 to 2030.

- Medium to long-term demand is driven by civil and industrial fibers, engineering plastics upgrades, and functional film expansion.

- Integrated layouts (Benzene-Cyclohexanone/KA Oil-CPL-PA6) enhance raw material and energy synergies, strengthening anti-cyclical capabilities.